Everything You Need to Know About litho printing

Wiki Article

A Comprehensive Overview to Understanding Litho Printing Techniques

The globe of litho printing, a technique originating from the late 18th century, is a fascinating mix of background, art, innovation and scientific research. Remain with us as we trip into the captivating realm of litho printing.The Historical Advancement of Litho Printing

The historical trajectory of litho printing, a crucial innovation in the realm of interaction, is an exciting story of human ingenuity. The procedure advanced with the advent of the rotating press, which substantially boosted performance. Each stage of litho printing's development showcases humankind's unrelenting search of performance and top quality in aesthetic interaction.Deciphering the Science Behind Litho Printing Inks

Progressing in the exploration of litho printing techniques, the focus now changes to the scientific research behind litho printing inks. The make-up of these inks, their drying out process, and color mixing techniques develop the backbone of this intricate art form. Recognizing these aspects is crucial to mastering the craft and attaining the preferred print results.Make-up of Litho Inks

In lithographic printing, the fundamental role of litho inks can not be overemphasized. Pigments, the color-providing components, are carefully ground bits put on hold in the car, a fluid that carries the pigment onto the printing surface. Each element plays a vital part in the last print's quality, making the accurate formula of litho inks a detailed scientific research.Ink Drying Process

From the make-up of litho inks, attention transforms to the interesting process of ink drying out. The drying out process is crucial, as it impacts the final print's high quality and durability. 2 key approaches are used in litho printing: oxidative drying and absorption. Oxidative drying out involves the ink reacting with oxygen in the air to form a hard, completely dry movie. This technique offers a sturdy surface, yet can be slower contrasted to absorption. Absorption, on the other hand, includes the ink leaking into the paper fibers, which is a much faster procedure yet can cause less lively shades. The choice between these techniques is dependent upon elements such as print speed demands, the paper type made use of, and the preferred coating.Color Combining Techniques

While the drying out procedure plays a vital function in litho printing, the scientific research of shade blending techniques holds equivalent significance. This is an intricate procedure that includes the mindful mixing of primaries: cyan, magenta, and yellow, in differing percentages to attain a large variety of hues. The addition of black ink, called 'key', helps in regulating the intensity and depth of the shades. The science behind litho printing inks additionally considers the openness of the ink, which impacts exactly how shades overlay and mix. To accomplish an effective shade mix, print experts need to likewise comprehend the details of ink actions, color theory, and the physical residential or commercial properties of the substrate on which the ink is applied.The Art and Design Elements in Litho Printing

Litho printing takes a breath life into art and design through its unique elements. Litho printing accommodates a selection of shades, making it possible for musicians to produce dynamic and lively prints. This combination of precision and flexibility makes litho printing a preferred option for several musicians and designers.Modern Applications of Litho Printing Methods

Litho printing techniques have actually discovered substantial usage in the contemporary industrial market. Its impact and significance remain to grow with the arrival of new advancements and technologies in the field. This section will check out these contemporary applications and the transformative function they play in the printing industry.

Industrial Litho Printing Utilizes

Litho printing continues to be a vital part of the commercial sector. High-volume printing jobs, such as the manufacturing of books, papers, and product packaging, count on litho printing for its ability to deliver superior photo high quality and cost effectiveness. Litho printing also provides a wide color range, superior to that of digital printing.Innovations in Litho Printing

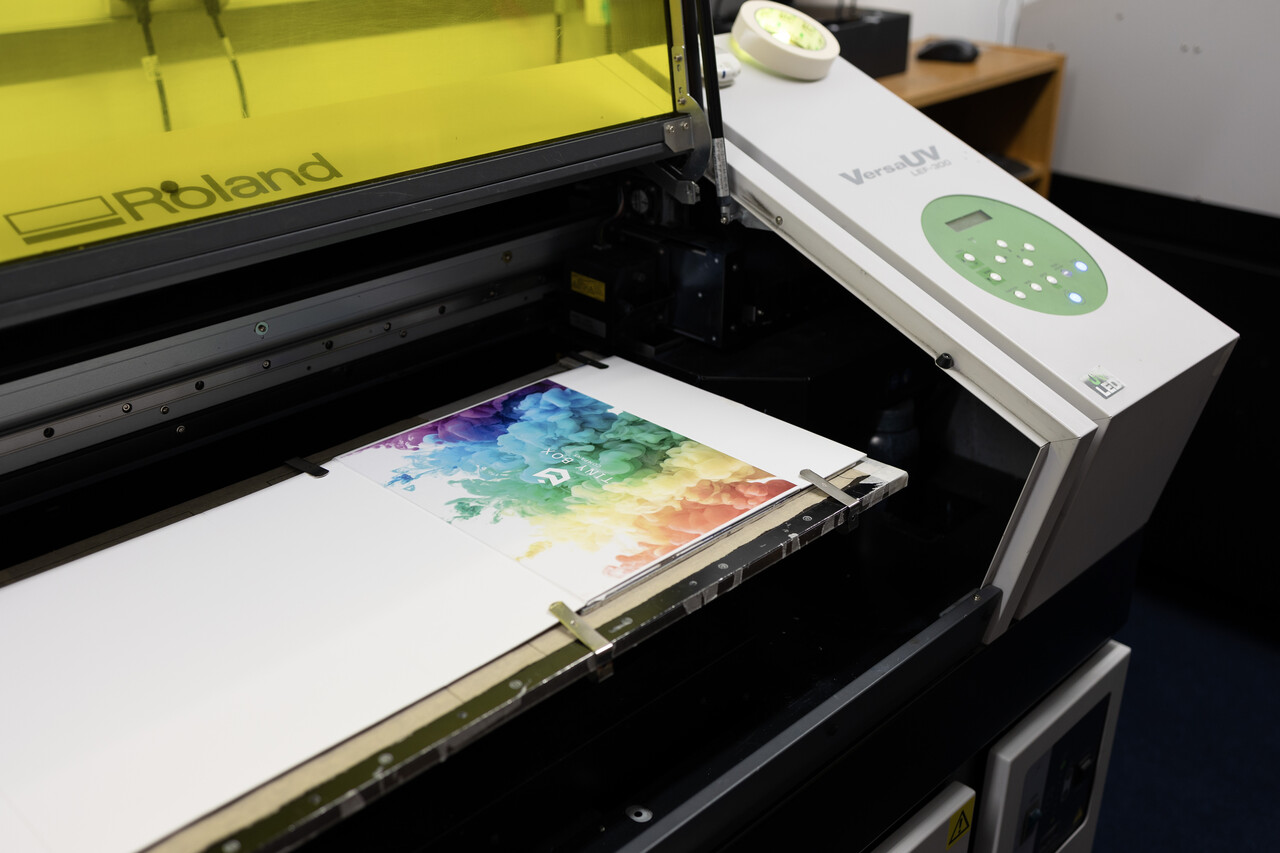

Pressing the boundaries of standard techniques, contemporary innovations have fueled a host of developments in litho printing. These breakthroughs have not just improved the top quality and performance of litho prints yet likewise broadened its application extent. One famous growth is digital litho printing, which combines the merits of electronic modern more info here technology with litho's high-grade result. This crossbreed model uses faster setup times, reduced waste, and allows on-demand printing. An additional significant advancement is the intro of eco-friendly inks. basics These inks, made from veggie or soy-based services, have considerably decreased the sector's environmental impact. litho printing. Additionally, the growth of innovative plate modern technology has structured the printing process, resulting in sharper pictures and boosted color fidelity. These technologies underscore the long-lasting significance of litho printing in the modern globe.Discovering the Refine of Litho Printing: Detailed

Obstacles and Solutions in Contemporary Litho Printing

Regardless of the precision and practice that litho printing proudly upholds, it is not without its set of modern challenges. The most widespread problems consist of the high initial setup cost, difficulty in printing variable data, and ecological concerns as a result of chemical use. Services are emerging as technology progresses. Digital litho printing permits affordable brief runs and very easy modification, attending to the issue of variable data. Environmentally-friendly inks and much safer plate-making procedures reduce ecological problems. Furthermore, improvements in automation have minimized labor prices, additionally democratizing the lithography procedure. Hence, while there are challenges, the litho printing sector is proactively adjusting to meet them head-on, ensuring its importance in the future.

Final thought

To conclude, litho printing, with its rich history and clinical complexities, holds a significant area in the print market. As the overview exposes, it's a synthesis of art and modern technology, with modern improvements guaranteeing its relevance. The industry faces challenges that call for ingenious remedies, with an emphasis on automation and sustainability. The future of litho printing rests on its capability to adapt to these altering demands, verifying its long-lasting worth in an evolving market.

Report this wiki page